CNC Machining is Profitable – Know the Full Insights!

Who doesn’t like the precision that saves time too? Yes, everybody enjoys it when you save your time and at the same time, serve accurate work. Likewise, CNC Machining Milling levels up the meaning of precision and perfection through its operational work.

CNC stands for Computer Numerical Control and it suggests the technological revolution in the manufacturing sector. It performs manufacturing activities that are listening to computer software. Many businesses such as take the help of CNC machine services and make the most out of their investment.

No matter the size of the production, this state-of-the-art technology can handle it all. Know the full overview of CNC Machining and its benefits for a manufacturer to meet his specific needs.

A Brief Introduction to CNC Machining

Several software programs controlled the CNC machining milling processes. With the development of advanced technology and innovation, this example is setting its bar as the computer is controlling business operations.

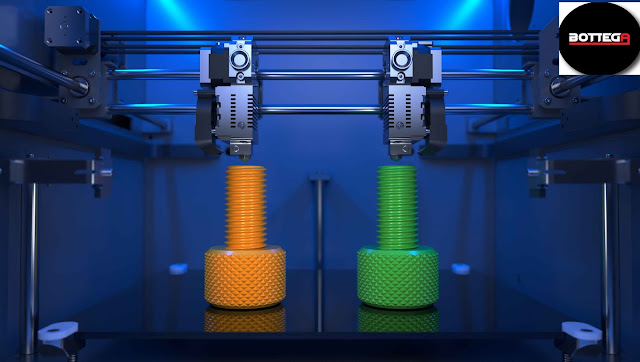

CNC milling machines turn a three-dimensional Computer Aided Design (CAD) model into a set of computer instructions. These control the CNC machine and equipment and automatically move the workpiece. Industries such as Automotive, Agriculture, Medical, Electronics, Construction and so on are taking advantage of CNC machines and achieving their business goals.

Manual Machining Vs CNC Machining

Nowadays, industries are switching to CNC Machining and there are many reasons behind it. If you are willing to achieve uniform results in terms of time and quality, a CNC machine is more beneficial than a manual one. In addition, if your business’s production is on large scale and meets the deadline too, then it is the preferred technology to utilise.

The CNC machine is safer than a manual milling machine. It has low risks of injury to the workers and only a person who has knowledge can conduct the production on this machine. It also saves the money of hiring more labour as it requires the minimal intervention of people. One can manage work effortlessly.

Pros of using CNC Machining Services

- Precision & Perfection

The one thing you need to follow is perfection and precision. CNC machining has the capability of serving the accurate precision we need in the manufacturing process. There is no chance of human error while using the CNC machines as it depends on the command of computer software. With precise tool settings and accurate command, you can achieve your goals in minutes.

- More Production in Minimum Time

Of course, machines can work more than a human. In industries where large-scale production is in action , it is advisable to use these contemporary machines instead of conventional ones. They will reduce your production time and carries out the process more efficiently.

- Versatility

You can’ imagine the flexibility characteristic of CNC machining. The machine can cut and drill at various axes, different tools, and different materials as well. It can produce simple to complex things and is beneficial for every project, no matter the shapes and sizes.

Install CNC Machine Today!

Apart from the above benefits and insights, we’ve much to tell you regarding CNC machining milling services and perks. Moreover, if you are working as a manufacturer or operator, stay ahead of the competition by installing CNC machining services that offer only precision and accuracy.

Comments

Post a Comment