How Commercial 3d Printing Services Can Transform Your Business?

In our fast-paced world, the ability to produce products quickly and efficiently has become a key factor in the success of any business. The ability to customize products to meet your specific needs can help you stand out from competitors while also saving time and money down the road.

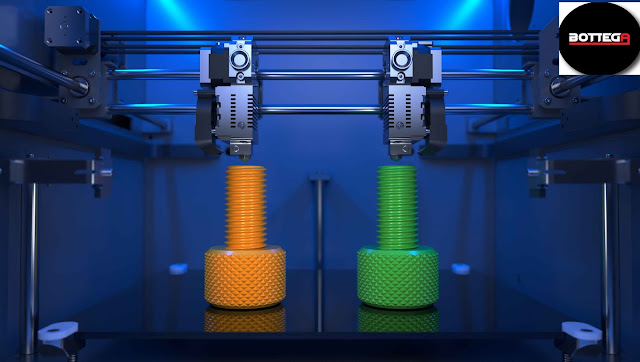

3D printing allows you to create prototypes or test new designs without investing in costly tooling or molding processes. You can also quickly and easily make small batches of products just for your store or office.

Automated, streamline production

When you use our Best Commercial 3D Printing Services, production is streamlined and automated. You no longer need to create tools or molds for each part. Instead, you send the design file to a 3D printer that prints out your product right then and there.

This means that you can get your products made much faster than if they were produced traditionally because there's no tooling process involved -- which also means there won't be any delays due to tooling being done incorrectly or taking too long to create!

Optimized product quality and output

Commercial 3D printing services can help you to produce products with a higher degree of precision, accuracy and durability. This is especially beneficial if you are manufacturing complex parts that require intricate details. For example, the 3D printing process allows engineers to produce parts with diameters as small as 0.01mm while also ensuring that they're watertight and leak-free.

In addition to being able to create more complex products, commercial 3D printers also allow designers to create parts that are more durable than those produced through traditional manufacturing methods such as injection molding or machining plastic or metal materials into their final form (such as milling).

Cost savings in manufacturing

- Reduced cost of production: 3D printing enables you to create prototypes in a fraction of the time it would take with traditional manufacturing methods, meaning that you can test out new designs and make changes more quickly.

- Reduced lead times: Once your prototype has been approved for production, 3D printing will enable you to get the product out faster than if you were using traditional manufacturing methods. This means that there's less risk involved if something goes wrong during development because there's no need for expensive tooling or large batches of parts being produced before they're ready for sale or use.

- Reduced waste: With traditional methods like injection molding and die casting, any excess material used during production goes straight into landfill--this isn't ideal for both environmental reasons (the amount of carbon dioxide emitted by burning fossil fuels) as well as financial ones (it costs money). With 3D printed parts however all waste is recyclable so there's no need for landfill sites which helps reduce costs further still!

Customization without the need for tooling

With 3D printing, you can create customized products that are unique to your business. You can create prototypes and test them before manufacturing large quantities of the final product.

With 3D Printing, there's no need for tooling or mold creation; this means that the time it takes to get a new product on the market will be much shorter than with traditional manufacturing methods.

Conclusion

Commercial 3d printing services is one of the most exciting technologies to come along in decades. It allows businesses to make things that were previously impossible, with less time and money than ever before. With the right 3D printer and materials, you can create products that are unique and customized for each customer without having to invest in tooling or molding costs. This means less waste and more profit for you!

Comments

Post a Comment