The Basics Of CNC Machining - What You Need To Know?

CNC machines are a type of computer-controlled milling machine, which means that they have the ability to program movements in three dimensions. The use of CNC machines has been growing rapidly over the past few years, and it is expected that this trend will continue for years to come. In fact, in many industries such as medical technology and aerospace manufacturing, CNC machines have become an essential part of their production process.

CNC Machining is a process that allows you to create precise parts by controlling the position of a cutting tool with respect to your material, based on commands from a computer program. It's a type of automated manufacturing, where the toolpaths are programmed into the control software before they're executed by the machine itself.

Benefits of CNC Machining

Benefits of CNC Machining:

- Reduced production time. A CNC machine is capable of producing parts in less time than a manual lathe or milling machine because it can perform complex operations much more quickly than a human operator.

- Increased precision and accuracy. A CNC machining process involves several steps that are repeated over and over again, which allows for much greater precision than hand-operated tools, which means that your finished product will be more accurate as well as look better overall since there won't be any visible errors in its surface quality due to human error during assembly or fabrication processes!

- Improved quality control standards mean increased safety for workers who handle these products on a daily basis (and even those who don't!). They also make sure all components meet stringent requirements before they're sent out into marketplaces around world so consumers can rest assured knowing they're getting exactly what they paid money for without having worry about whether or not something might break down after only one use."

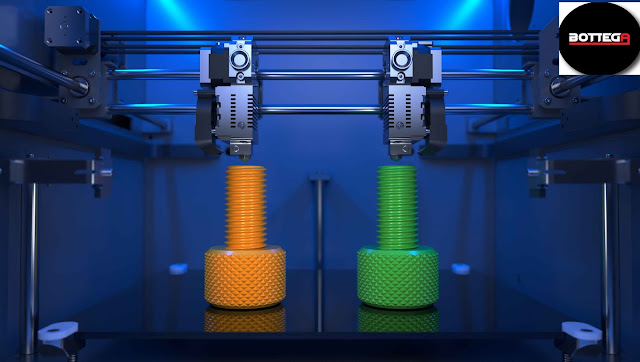

Types Of CNC Machines

There are several types of CNC Machines, each with its own advantages and limitations. The type you choose depends on your needs and budget.

The most common types include:

- Cartesian (XYZ) systems: These machines have three axes that move at right angles to one another. They're typically used for cutting flat pieces of material, like metal sheets or boards.

- Spindle-based systems: Although they don't offer the same range as cartesian systems, spindle-based models are more affordable because they use smaller motors and fewer components. This makes them ideal for hobbyists who want to make smaller parts at home but don't need high-end capabilities like those found in industrial shops or machine shops!

Conclusion

CNC machining is a great way to make your parts, but it can be confusing to understand at first. We hope this article has helped you understand some of the basic concepts of CNC machining and how it can be used in your business. If you want more information on how we can help with your project or need advice on what type of machine would work best for you, please contact us today!

Comments

Post a Comment