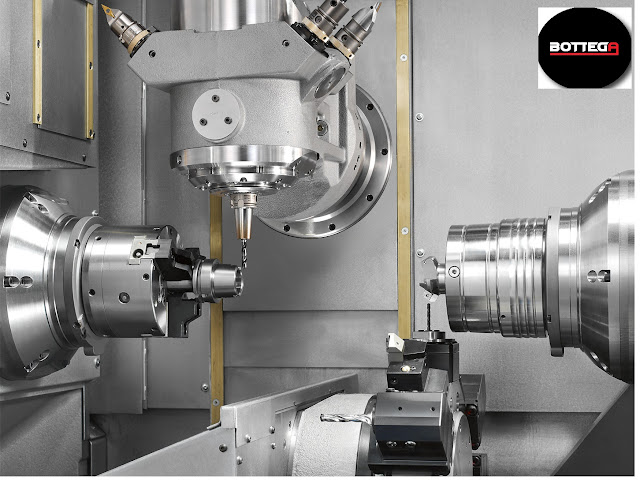

5 High-Speed CNC Machining Tips for Beginners

CNC machining nz is a great way to get started in the manufacturing world. The process of using computer software to control a machine that will carve out parts is a simple one, but there are still some things that you can do to improve your workflow and increase productivity. Here are five tips for beginning CNC machinists:

Invest In Quality Tooling

You want your machine to be able to produce the best parts possible, and that means investing in quality tooling. Tooling can be expensive, but it will last longer than cheaper options and produce better results.

You'll also want to invest in tooling compatible with your CNC machine so that you don't have to constantly adjust or replace it as you learn more about machining techniques.

Good-quality tooling will help ensure that every part comes out looking exactly as intended - no more guessing if something is off because of bad tools!

Warm Up Your Spindle And Machine

- The spindle and machine should be at operating temperature before starting your job. This will make it easier to keep them at their optimal performance level, and will allow you to run your parts without issue.

- Heating may take longer than expected, so plan accordingly! You may have to start heating earlier than you think if the part is large or has multiple machining operations on it. If this is the case, make sure that your material has sufficient time between steps so that they can cool down before being loaded into the machine again (or else they could warp).

- Cooling down may also take longer than expected--especially if there are multiple machining operations being performed by different tools with different cutting speeds and feeds per tooth/inch numbers involved in each operation's toolpaths (e.g., roughing vs finishing).

Pair Small Tools With High-Speed Spindles

If you're using a high-speed spindle, it's important to pair your tooling with small cutting tools. Smaller tools will reduce the amount of heat that is generated in the material being machined and increase their life.

If you are using larger cutting tools, however, they may not be able to take advantage of all of the speeds available on your CNC machine and could cause problems with vibration or chatter marks on your parts if they're too large for its capabilities.

Use Dynamic Tool Paths

Dynamic tool paths are often used in the aerospace industry and other demanding manufacturing environments.

Dynamic tool paths can be used for high speed machining, which is helpful when you need to machine a part with high accuracy. In fact, dynamic tool paths are one of the most accurate ways to machine parts with complex geometry at high speeds.

Outfit Your Machine With Reliable Work holding

Work holding is the key to high-speed cnc machining nz, but it's also essential for accuracy, repeatability and safety. In fact, it can make or break your CNC project.

If you're new to CNC machining and don't know where to start with work holding strategies--or if you've been using them for years and want some tips on how best to implement them--we have some great suggestions for improving your setup.

Conclusion

CNC cnc machining nz is a great way to get started in the world of 3D printing. It requires less investment than other methods, such as laser cutting, and can be used for creating prototypes or small batches of parts.

For More Information Vist : https://bottega.co.nz/

Comments

Post a Comment