Why You Should Use CNC Machining Services?

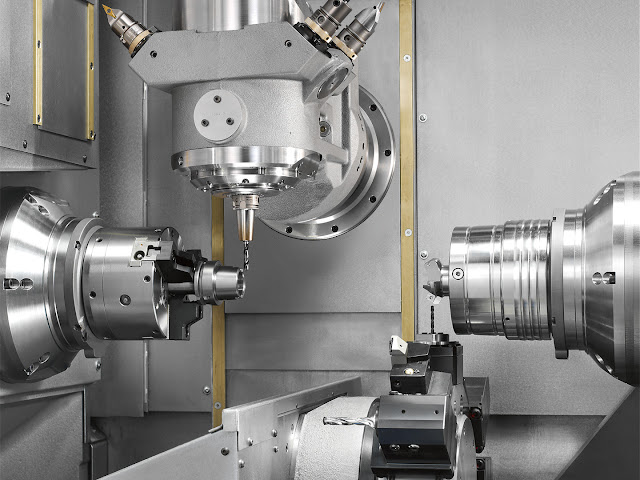

For those of you who don't know, CNC stands for "computer numerical control." Simply put, it's a machine that uses a computer to control its movements. This allows it to perform tasks with high precision and accuracy. If you're looking for a way to improve your business, then Top CNC Machining Services near me might be the answer for you!

Precision and Accuracy

Precision and accuracy are two important considerations when it comes to machining. Precision refers to the ability of a machine tool to produce parts within a specified tolerance range. Accuracy, on the other hand, refers to how much variation there is between parts produced by different machines.

CNC machining offers higher precision compared to manual machining because your workpiece is held on a machine table at all times during the cutting operation. This eliminates any human errors that can occur when working with tools manually or even using automatic lathes where there is no tool change involved (one tool will be used for every operation).

With CNC milling, you have greater control over what part will be made as long as you input this information into your CAD program beforehand; thus allowing you to achieve better results in terms of precision and accuracy when compared with manual methods which may require more time spent on set up processes before each part can be produced successfully.

Reduced Material Waste

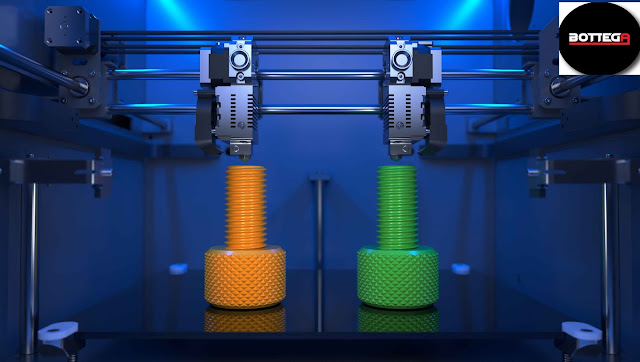

CNC machining services are a great option for companies looking to reduce material waste, processing time, setup time and scrap. With CNC milling machines, the operator can program the machine to create intricate shapes while maintaining the integrity of complex parts.

In addition to keeping these components intact during production, CNC milling machines also allow you to reuse stock material that may have otherwise been discarded. This reduces your overall cost per part by reducing material waste and allowing you to use your resources more efficiently.

Low Labor Requirements

CNC machining can be done by a single operator, which means less labor costs. To run an entire production line, you’ll need several operators that are in charge of different machines and processes. When all the processes are automated with CNC Machines, those human operators are no longer needed.

CNC machines also require less physical labor compared to traditional methods of manufacturing. With manual labor, workers must manually perform repetitive tasks such as drilling holes on small pieces of metal or plastic parts for hours at a time with heavy tools such as drills and grinders until they get tired enough to go home for the day.

Not only does this take up valuable time from each employee but it also causes fatigue and other health problems due to repetition-based injuries like carpal tunnel syndrome (leads to sore wrists) or tendonitis (a painful inflammation of tendons). In contrast, cnc machining services near me uses automated machines programmed according to customer specifications so that each step is performed without any human involvement—meaning there won’t be any repetitive stress injuries due to overuse of body parts during work hours!

Conclusion

CNC machining services are a great way to increase productivity, reduce material waste and improve the quality of your products. This technology has been around for decades now, so it’s time to give it a try!

Comments

Post a Comment